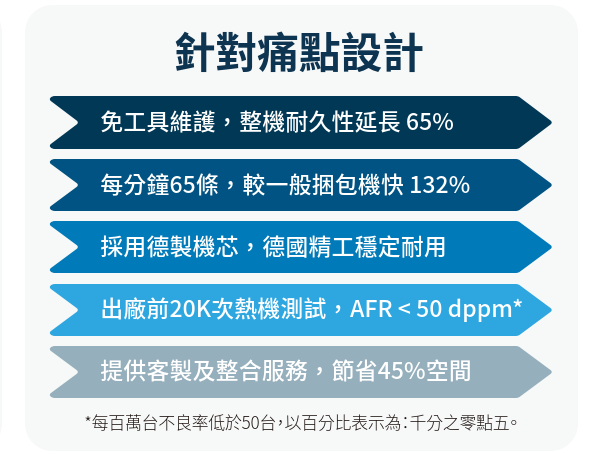

TRANSPAK · World-class baler brand-brand authorized partner

Description of the models sold

TRANSPAK Brand Advantages

All TRANSPAK products are manufactured in Taiwan factories that are certified by the ISO 9001 quality management system.

Qianbin Industrial is the brand's authorized partner in Taiwan

TRANSPAK, a leading Taiwanese brand, produces the Helios H-45L handheld high-speed electric baler, utilizing advanced friction welding technology to eliminate the need for metal strapping, effectively reducing the cost of baling consumables. Its user-friendly, one-touch operation not only allows for quick and easy baling, but also significantly reduces labor costs. The Helios H-45L can accept both PET and PP strapping, making it suitable for baling a wide range of flat products, whether horizontally or vertically, ensuring high-quality baling efficiency. Machine features High-end friction welding technology is used to ensure perfect welding of the straps, with high reliability. User-friendly one-button operation can easily complete packaging, welding and cutting within 3 seconds. The tightening force and welding time are adjustable, and the knob design makes the settings easy. Bosch's new lithium-ion battery technology can print up to 512 strips after charging (depending on the quality of the strap) Flexible operation mode: automatic/semi-automatic operation mode Quick strapping design reduces the time required for operation Scope of application It can be used for vertical or horizontal packaging of various flat goods such as cartons, pallets, wooden boxes, building materials, steel, plates, etc. Optional accessories Bottom guard plate: scratch-resistant and wear-resistant, reinforced structure Fixed/movable hook: convenient for hanging tools, making operation more labor-saving Technical data Strapping tape type PP & PET Strapping tape width 9 mm (H-45L-1-09) 11 - 13 mm (H-45L-1-12) 15 - 16 mm (H-45L-1-16) Strapping tape thickness PP 0.55 mm - 1.05 mm PET 0.50 mm - 1.05 mm Maximum tightening force Up to 250 kg Battery Bosch Li-ion battery 18VDC, 4.0Ah Weight 4.4 kg

TRANSPAK's latest generation of handheld high-speed electric balers, the H-46 Kronos, utilizes advanced friction welding technology, eliminating the need for metal straps and effectively reducing baling costs. Its digital operation panel and one-touch fully automatic strapping mode offer intelligent operation, enabling quick and easy strapping and significantly reducing labor costs. The H-46 Kronos can accept both PET and PP strapping, making it suitable for a wide range of industries, meeting both horizontal and vertical strapping needs with high-quality strapping and excellent efficiency. Features include advanced friction welding technology, ensuring perfect strapping and high reliability. User-friendly one-touch operation allows for easy strapping, welding, and cutting in just 5 seconds. A German-made brushless DC motor ensures precision and durability. The intelligent digital operation panel features up to six strapping modes for quick selection, and displays battery capacity and error signals for enhanced user-friendliness. The new Bosch lithium-ion battery boasts over 1,000 recharges and a long lifespan. After charging, in high-tension mode, it can produce up to 415 PP straps or 320 PET straps. The strap width can be easily changed. The tool can automatically adjust the cooling time of the adhesive strap. The perfect weight balance and ergonomic grip design make it easier and more labor-saving to use. Scope of application: It can be used for vertical or horizontal packaging of various flat goods such as pallets, cartons, wooden boxes, building materials, steel, plates, etc. Optional accessories: Bottom guard plate: scratch-resistant and wear-resistant, with reinforced structure. Hook: convenient for hanging tools and saving operation. Technical data Model specification H-46A Light & Universal application H-46B Heavy industry application Maximum tightening force 250 kg 400 kg Applicable strap width 11 mm - 13 mm, 15 mm - 16 mm 15 mm - 16 mm, 19 mm Applicable strap thickness PP 0.60 - 1.05 mm PET 0.50 - 1.05 mm PP 0.75 - 1.30 mm PET 0.60 - 1.30 mm Tool weight (including battery) 4.3 kg 4.4 kg Battery Bosch Li-ion battery 18V, 4.0Ah Bosch Li-ion battery 18V, 4.0Ah Charger Bosch 220V 50Hz 1PH Bosch 220V 50Hz 1PH

Tauris TP-601D is an enhanced automatic strapping machine for PP strapping. With the value-added features, Tauris TP-601D is the most powerful machine with the best price to performance ratio product in its category for general applications.

Features

Reliable and robust strapping head

Electronic tension control

Auto strap feeding

Auto strap ejector

Short feed sensor

Auto strap refeed

Strap end ejector

Multiple methods of cycle initiation

Lubrication free strapping head

Adjustable weld-cooling time

Options

Smoke exhaust system with carbon filter

Emergency stop switch

Table without free roller

PU casters

Technical Data

Capacity Up to 29 cycles/minute

Strap Width 8 mm, 9 mm, or 12 mm

Tension Range 7 to 45 kg

*up to 70 kg on request

Maximum Package Weight 100 kg

Weight 220 kg

Electrical Requirements 110V, 220V, 230V, 240V 50/60Hz 1PH

220V, 380V, 400V, 415V 50/60Hz 3PH

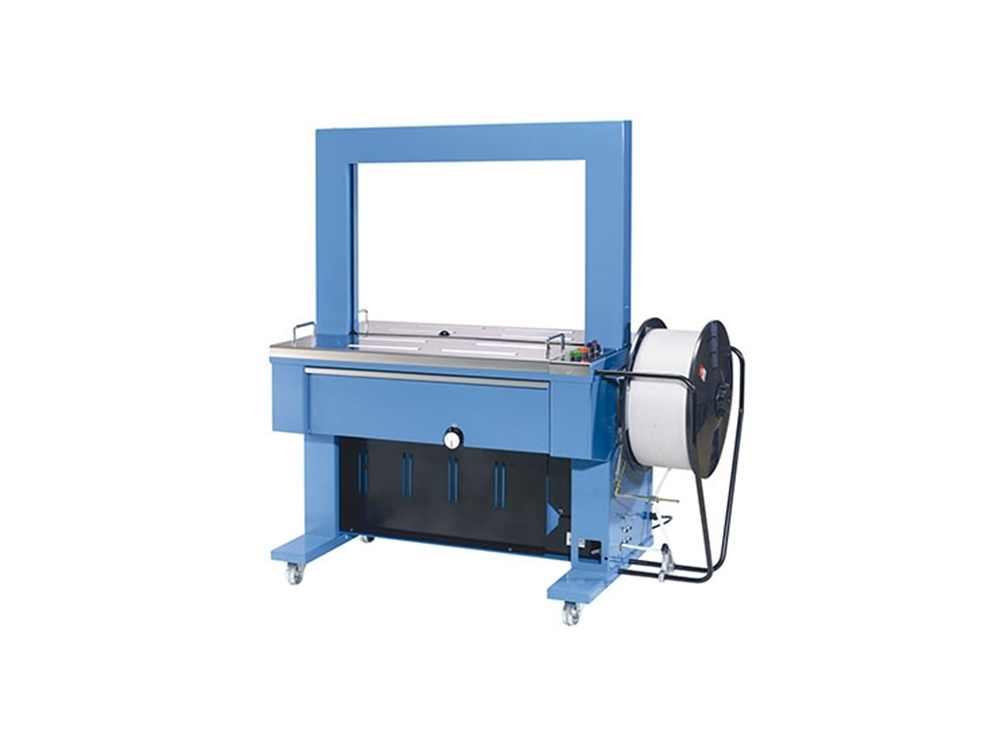

The TP-702 Mercury high-speed baler boasts world-class design, user-friendly operation, and easy maintenance. With a maximum baling speed of 65 strips per minute, it ranks among the industry's top balers. The TP-702 Mercury can be used for a wide range of products, including general packaging, corrugated boxes, printed materials, and other products. Over tens of thousands of TP-702s have been sold to over 90 countries worldwide. Designed and manufactured entirely in Taiwan, the TP-702 offers reliable quality. Features: State-of-the-art baling head design with tool-free maintenance (patented); Waist strap changer (patented); Rotating control panel; Automatic spring-loaded function; Automatic tail strap removal; Optional accessories and related models: Photoelectric eye switch; Removable foot switch; Rear fixed foot switch; Low tabletop (770-820 mm); Various frame sizes; Stainless steel model: TP-702S; Green energy-saving technology; Technical data: Strapping speed: 65 straps/min (TP-702-59); 60 straps/min (TP-702-12); Strap type: PP strap; Strap width: 5 mm, 6 mm, or 9 mm (TP-702-59); 12 mm (TP-702-12); Clamping force: 1-32 kg (TP-702-59); 1-55 kg (TP-702-12); Voltage: 110V, 220V, 230V, 240V, 50/60Hz; 1PH

Mercury Transit TP-702A is a fully automatic strapping machine with roller-driven table for production and packaging lines. It is suitable for 5 mm, 6 mm, 9 mm, or 12 mm PP strapping. TP-702A is the fastest and most reliable strapping machine for general applications on the market today.

Features

Robust & compact mechanical strapping head

Roller-driven table for heavy load packages

Waist-high auto strap feeding

Free access to strap guides (patents registered)

Electronic tension control

Auto strap ejector

Strap end ejector

Hinged top plates

Multiple strap function

Variable conveyor speed between 15 and 60 meters/minute

Up and down stream interlock with complete plug connection

Easy bundle flow direction change

Good for heavy packages

Adjustable table height between 800 mm and 900 mm

Options

Siemens PLC

Light tower with low strap sensor

Energy saving transit with auto sleep mode

Strapping in the center of the bundle & strapping controlled with 2 photo eyes

Lower adjustable table height (750 mm – 900 mm)

Dual channel E-Stop

Green Tech

Technical Data

Strap Width 5 mm, 6 mm, 9 mm or 12 mm

Tension Range 1-32 kg (for 5 mm, 6 mm, 9 mm)

1-45 kg (for 12 mm)

Capacity Up to 36 packages/minute

(Cycle speed up to 65 cycles/minute)

Maximum Package Weight 80 kg

Weight 287 kg

Electrical Requirements 110V, 220V, 230V, 240V 50/60Hz 1PH

220V, 380V, 400V, 415V 50/60Hz 3PH

The TRANSPAK TP-702B high-speed, unmanned, fully automatic strapping machine features a state-of-the-art design with multiple strapping modes to accommodate a wide variety of materials. Utilizing the popular TP-702 Mercury strapping head, which has sold tens of thousands of units in 89 countries worldwide, the TP-702B is the fastest and most stable unmanned, fully automatic strapping machine on the market. Machine Features: Advanced baling head design (patented); Tool-free maintenance; Belt drive table; Flip-up table for easy maintenance; Suitable for baling small packages; Automatic strap threading; Automatic bounce function; Automatic tail removal; Adjustable table height; Quick strap change; German-made, high-stability DC brushless motor; Interoperable with upstream and downstream equipment for unmanned production lines; Optional accessories and related models: Siemens PLC control; Strap load detection; Three-color light; Tabletop sleep mode; Automatic center strapping based on bale size; Dual photoelectric sensors; Strapping control; 200 mm extension table available; Multiple frame sizes; Stainless steel model TP-702BS; Green and energy-saving technology; Technical Data: PP strapping strapping specifications: 5 mm, 6 mm, 9 mm, or 12 mm; Speed: 40 bales/min; Clamping force: 1-32 kg (5, 6, 9 mm); 1-55 kg (12 mm); Voltage: 220V 50Hz 1PH; 380V 50Hz 3PH

Mercury Transit TP-702BH is a fully automatic strapping machine with belt-driven table and Siemens PLC & HMI for production and packaging lines. It is suitable for 5 mm, 6 mm, 9 mm, or 12 mm PP strapping. TP-702BH is the fastest and most reliable strapping machine for general applications on the market today.

Features

Robust & compact mechanical strapping head

Belt-driven table

Equipped with Siemens PLC and HMI as standard

Waist-high auto strap feeding

Free access to strap guides (patents registered)

Electronic tension control

Auto strap ejector

Hinged top plates

Diverse strapping patterns

Variable conveyor speed between 10 and 60 meters/minute

Up and down stream interlock with complete plug connection

Easy bundle flow direction change

Good to strap small package with minimum size 120 mm in width and 10 mm in height

Adjustable table height between 800 mm and 900 mm

Options

Dual channel E-Stop

Light tower with low strap sensor

Energy saving transit with auto sleep mode

Strapping in the center of the bundle & strapping controlled with 2 photo eyes

Extension belt-driven table of 200 mm on upstream and downstream sides

Lower adjustable table height (750 mm – 900 mm)

Automatic tension control by package height detection (3 stage tension)

Automatically determining the number of straps by package length

Signal exchange via 16 pin connector

Low package bypass

Green Tech

Technical Data

Strap Width 5 mm, 6 mm, 9 mm or 12 mm

Tension Range 1-32 kg (for 5 mm, 6 mm, 9 mm)

1-55 kg (for 12 mm)

Capacity Up to 40 packages/minute

(Cycle speed up to 65 cycles/minute)

Weight 228 kg

Electrical Requirements 110V, 220V, 230V, 240V 50/60Hz 1PH

220V, 380V, 400V, 415V 50/60Hz 3PH

The TP-702P Mercury features dual pressure bars, making it ideal for loose bales or those requiring compaction before baling. It is widely used for baling corrugated boxes, plastic sheets, paper, bags, and other products. Its dual pressure bars flatten the bale before baling, enhancing its compactness and stability. Utilizing the same world-class baler head as the TP-702 Mercury, it offers user-friendly and easy maintenance. With a maximum baling speed of 47 bales per minute, it is a top-tier baler in the industry. Designed and manufactured entirely in Taiwan, it offers reliable quality. Features: Double down levers, State-of-the-art baling head design, Tool-free maintenance (patented), Waist strap changer (patented), Rotating control panel, Automatic pop-up function, Automatic tail strap removal. Optional accessories and related models: Photoelectric eye switch, Removable foot switch, Rear fixed foot switch, Low tabletop (770-820 mm), Various frame sizes, Stainless steel model: TP-702PS, Green and energy-saving technology. Technical data: Strapping speed: 47 straps/min (TP-702P-59), 44 straps/min (TP-702P-12), Strapping type: PP strap, Strapping width: 5 mm, 6 mm, or 9 mm (TP-702P-59), 12 mm (TP-702P-12), Strapping force: 1-32 kg (TP-702P-59), 1-55 kg (TP-702P-12), Voltage: 110V, 220V, 230V, 240V. 50/60Hz 1PH

The TP-702RS Mercury is a high-speed baler designed specifically for small packages or round bales. Its unique tabletop gluing mechanism ensures fast and high-quality bales. Utilizing the same baler head as the TP-702 Mercury, it boasts a world-class design, user-friendly operation, and easy maintenance. With a maximum bale speed of 65 bales per minute, it is a top-tier baler in the industry. Designed and manufactured entirely in Taiwan, it offers reliable quality. Minimum product size for baling: 40 mm (W) x 10 mm (H) Minimum round bale size: Ø 32 mm x 2 pcs Machine Features Advanced baling head design Tool-free maintenance (patented) Waist strap change design (patented) Rotating operation panel Automatic pop-up function Automatic tail strap removal Optional accessories and related models Photoelectric eye switch Mobile foot switch Rear fixed foot switch Low tabletop (770~820 mm) Various frame sizes Stainless steel model: TP-702RSS Green and energy-saving technology Technical data Strapping speed 65 straps/min Strapping type PP strap Strapping width 5 mm, 6 mm or 9 mm Clamping force 1-32 kg Voltage 110V, 220V, 230V, 240V 50/60Hz 1PH

The TP-733H Castor III is TRANSPAK's next-generation fully automatic horizontal pallet baler, compatible with both PP and PET strapping, meeting diverse market demands. It utilizes the TP-733-SH ARES baling head, incorporating the latest DC brushless motor and advanced friction bonding technology. Its rugged design makes it easy to operate and maintain. It can be used with a variety of high-capacity, unmanned production lines, significantly improving production efficiency. Features: TP-733-SH ARES; Reinforced baler head with strap guide; Movable baler head; Siemens PLC control and touch screen; Tool-free maintenance; 180-degree flexible baler trolley positioning; Safety detection and protection device; Easy baler head replacement; Optional accessories: Tension balance (heart offset); Separate operation panel; Low strap load detection three-color emergency stop; Dual-circuit low tension (200 N - 1200 N); Remote switching of strapping parameters for side change (4-bit input) on the operation panel; 500 mm higher strapping space; Technical Data: Speed: 60 pallets/hour (three parallel straps); Strap type: PP or PET; Strap width: 12 mm, 15.5 mm, or 19 mm; Clamping force: 1,100 – 3,200 N (standard); 200 – 1,200 N (optional); Reel dimensions: Inner diameter 406 mm (standard); Inner diameter 200 mm / 230 mm / 280 mm (optional) Voltage: 220V, 380V, 400V, 415V 50/60Hz 3PH All TRANSPAK products are manufactured in Taiwan with an ISO 9001 certified quality management system.

The TP-733VLM Pollux III is TRANSPAK's next-generation fully automatic, side-strap pallet baler. It utilizes the TP-733-SH ARES baling head, incorporates the latest DC brushless motor, and advanced friction bonding technology. Its rugged design makes it easy to operate and maintain. The TP-733VLM can be used with either PP or PET strapping, making it suitable for vertical strapping of various pallets. It can also be used with high-capacity unmanned production lines, significantly improving production efficiency. Features: TP-733-SH ARES; Reinforced baler head; Siemens PLC and touch screen; Movable baler head; Flexible 180-degree positioning of the baler head; Easy-to-change baler head; Tool-free maintenance; Optional accessories: Tension balancing (heart offset); Heart group extension stroke extended to 700 mm; Separate operation panel; Low strap detection three-color emergency stop; Dual-circuit low tension (200 N - 1200 N) and pressure device (2000 N or 5000 N); Operation panel; No strap change signal during side change. This series includes the TP-733V fixed frame and fixed head; the TP-733VM fixed frame and movable head; the TP-733VLM movable baler head and movable head. Technical Data: Speed: 72 pallets/hour (vertical double strips); Strap Type: PP or PET strap; Strap Width: 9 mm, 12 mm, 15.5 mm, or 19 mm; Strapping Force: 1,100 – 3,200 N (standard) 200 – 1,200 N (optional) Reel size 406 mm inner diameter Voltage 220V, 380V, 400V, 415V 50/60Hz 3PH

The TP-6000 is an economy automatic strapping machine for PP strapping. Easy operation and simple maintenance. The proven quality and performance make TP-6000 the most cost effective solution for general applications.

Features

Lubrication free strapping head

External mechanical tension control

Multiple methods of cycle initiation

Affordable choice for every budget

Options

Short feed sensor

Smoke exhaust system with carbon filter

Table without free roller

PU casters (2 free and 2 with brake)

Technical Data

Capacity Up to 27 cycles/minute

Strap Width 8 mm, 9 mm, 12 mm, or 15.5 mm

Tension Range 7 - 70 kg

(CE version: up to 45 kg)

Weight 220 kg

Electrical Requirements 110V, 220V, 230V, 240V 50/60Hz 1PH

220V, 380V, 400V, 415V 50/60Hz 3PH

Consumables: Environmentally friendly certified shrink film

Qianbin Industrial integrates other international brands to provide joint services. Qiaofu materials - biodegradable products, Qiaofu foam, Genok special straps, Licocle wipes, Asotech moisture-proof solutions, Tesa tapes, Qiaoyilong industrial belts, and aluminum alloy related internationally certified materials are all designated brands of the international supply chain. Qianbin Industrial provides a truly one-stop intelligent sustainable material integration service.

CONTACT US

Choose us, service will not wait!

No matter when, we care about your needs!

Solve your problem instantly and give you peace of mind.

For product applications/technical information/warranty details/system integration, please contact Qianbin Industrial

We want to know your needs exactly so that we can provide the perfect solution. Let us know what you want and we’ll do our best to help.