Germany's tesa is one of the world's oldest (since 1906) and largest multinational adhesive tape manufacturers.

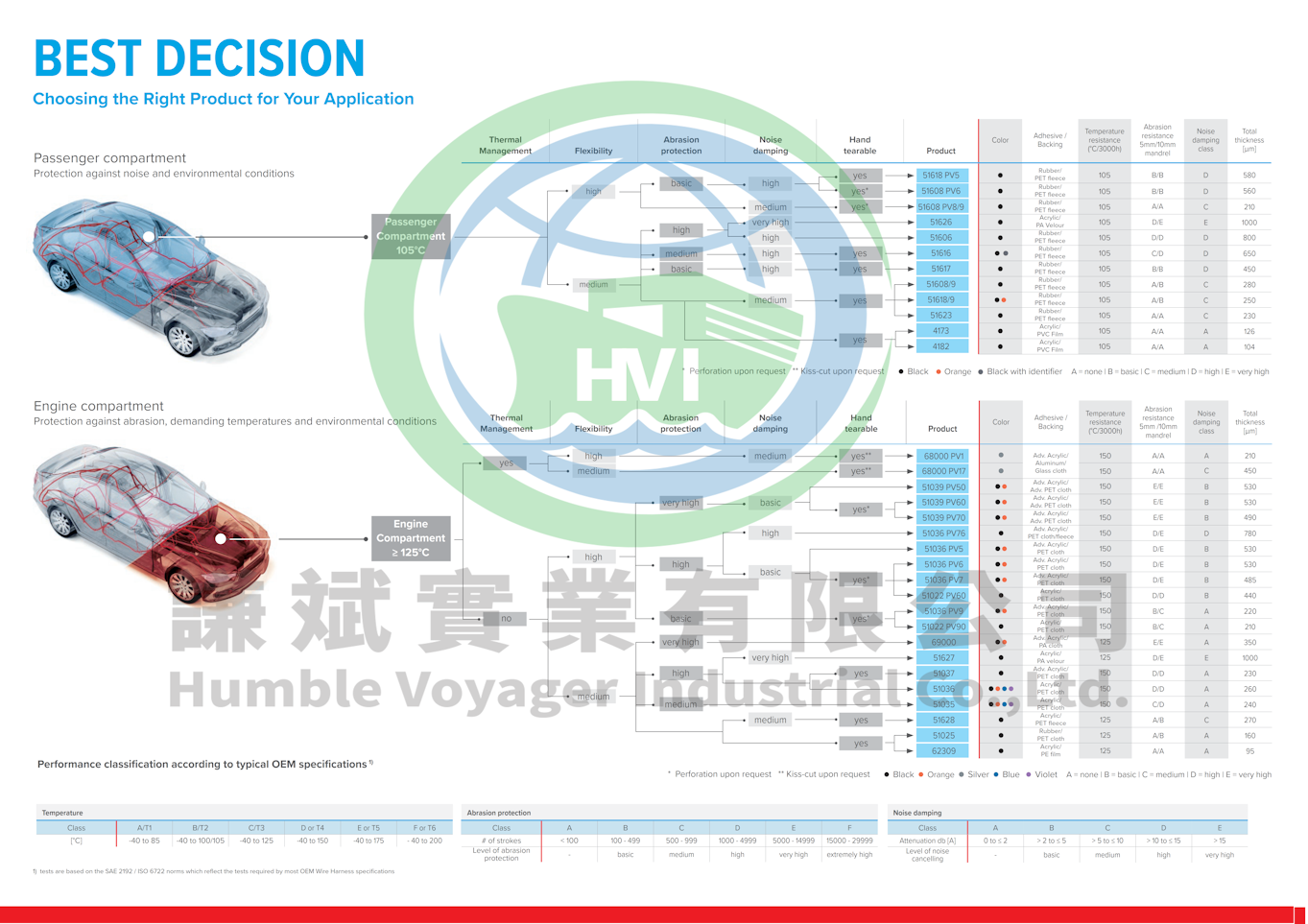

tesa's professional vehicle wiring solutions and historical evolution

#WireHarnessing #eMobility #ThermalManagement #AbrasionProtection

With the advancement of intelligent vehicles, young car owners are increasingly demanding "human-vehicle interaction" and easy access to basic social and entertainment functions within the car. This has led to the widespread use of more and more electronic and sensor devices in vehicles. This has led to increasingly complex and thicker wiring harnesses in certain automotive components. This has undoubtedly put pressure on the air quality in the already confined interior space and caused noise disturbances for drivers during driving. These issues will place higher demands on automakers' wiring harness fixing and assembly processes. As a partner of OEMs, tesa, drawing on its extensive experience in automotive wiring harness fixing, has developed a series of low-VOC wiring harness fixing tapes that meet the requirements of the automotive industry. Recently, tesa has developed a series of specialized wiring harness tapes to address customer challenges in wiring harness fixing and assembly, including difficult-to-bond materials, numerous wire harnesses, and tight processing times. These tapes offer exceptional initial adhesion compared to other wiring harness fixing tapes. As for the solution to automobile noise, the current treatment method on the market is mainly passive noise control, which mainly uses noise reduction tape and sound insulation tape at the joints of various parts of the car to reduce the vibration generated by the car while it is moving, thereby reducing noise.

As a world-renowned tape expert, Tesa Tape also has many excellent products for noise reduction and sound insulation. These tapes can be used in many places in the car to reduce the noise of the car.

Known as the "King of Hole-Plugging and Noise Reduction," tesa® 54715 is composed of a thick, mineral-filled PO and a high-bonding adhesive. It is ideal for sealing unwanted holes in car bodies. It provides noise reduction and a secure, reliable bond, even in difficult-to-apply areas.

tesa® 50118 is a reinforced felt tape suitable for automotive interiors. It is primarily used for the secure fixing of automotive wiring harnesses.

In addition to the two aforementioned automotive noise reduction tapes, tesa also offers other excellent noise reduction tapes such as tesa® 52210, tesa® ACXplus 7450, tesa® 50118, and tesa® 60606, which can help automakers eliminate noise hazards in various parts of their vehicles.

tesa noise reduction tapes are available in a wide variety and of high quality, reducing the noise of your car and giving you an extraordinary driving experience.

Qianbin Industrial is gradually stocking up on stock in the Taiwan market. Please feel free to contact us for inquiries.

German tesa tape general industrial wiring harness related tape solutions

tesa wire harnessing series -total solution

Regarding the applications related to wiring harnesses, Germany's tesa series products are diverse. We will differentiate and explain them by the following industrial applications, namely automotive, etc. If there are any questions not covered, please contact Qianbin Industrial directly for further consultation.

### The Future of Automotive Electrification and tesa Wiring Tapes

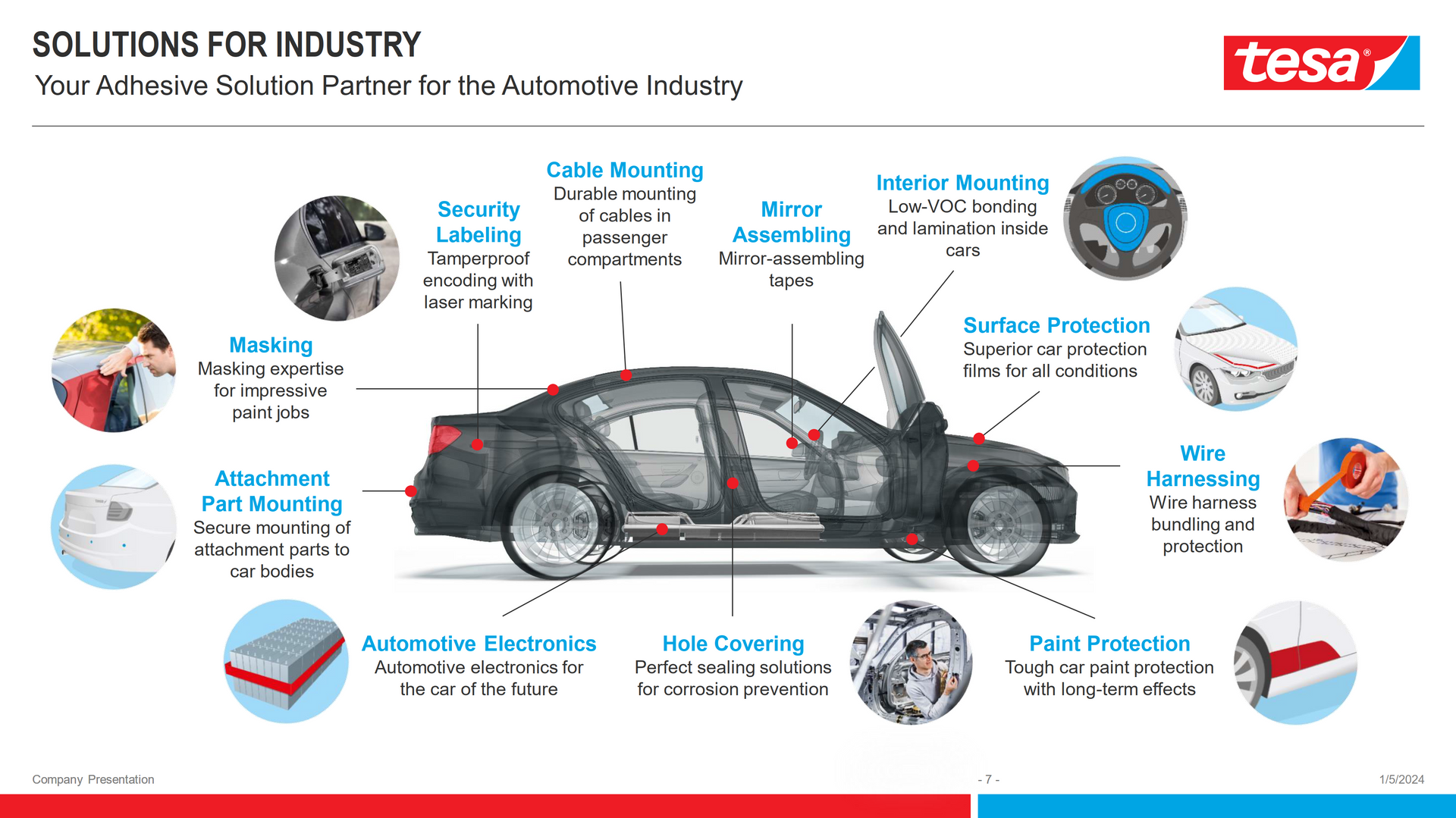

As the automotive industry transitions to electrification, managing wiring harnesses within vehicles is becoming increasingly important. Wiring harnesses are more critical than ever in electric vehicles, serving as the primary conduit for power and data transmission, ensuring interoperability between various vehicle systems. As a leading adhesive tape manufacturer, tesa's wiring harness tapes play a crucial role in this transformation.

#### The irreversible trend of automobile electrification

With increasingly stringent environmental regulations and growing consumer awareness, automakers are actively promoting the transition from internal combustion engines to electric vehicles (EVs) and hybrid vehicles (HEVs). This process has led to an increasing complexity and importance of the vehicle's wiring harness. The wiring harness not only needs to transmit high-power current to drive the motor but also ensures the stable transmission of data signals to ensure the normal operation of the vehicle's electronic systems.

#### Applications and advantages of tesa wiring harness tape

The wiring harness tapes provided by tesa are specially designed for automotive applications and offer the following outstanding advantages:

1. **High temperature resistance**:

The interior environment of a car is complex, especially in electric vehicles, where temperatures near the battery pack are high. tesa wiring harness tapes offer excellent high-temperature resistance, maintaining stability over time in high-temperature environments and protecting wiring harnesses from damage.

2. **Abrasion resistance and chemical resistance**:

During vehicle operation, wiring harnesses may be subject to abrasion and contact with chemicals. The abrasion and chemical resistance of tesa tapes ensures reliable protection of wiring harnesses in all kinds of harsh conditions.

3. **Noise reduction and vibration reduction**:

tesa wiring harness tape has excellent noise reduction and vibration reduction properties, which can effectively reduce the vibration and noise caused by vehicle driving and improve ride comfort.

4. **Easy to apply**:

tesa tapes are conveniently designed and easy to apply on the production line, improving production efficiency. Their strong adhesive properties and flexibility ensure that the wire harness is firmly fixed and can be flexibly applied in different locations.

#### Specific applications of tesa wiring harness tape in automotive electrification

1. **Battery wiring harness**:

The battery packs of electric vehicles require reliable wiring harness connections to ensure stable transmission of high currents. tesa tapes' high temperature resistance and excellent insulation properties make them ideal for wrapping battery wiring harnesses.

2. **In-vehicle electronic devices**:

In-car entertainment systems, navigation systems, and various sensors require stable signal transmission. tesa tape can effectively shield electromagnetic interference and protect the stability of data transmission.

3. **Body wiring harness**:

tesa tape can provide strong protection for the electrical connections in various parts of the car body, such as the lighting system and door lock system, ensuring stable and reliable electrical connections in these key parts.

### in conclusion

Automotive electrification is an irreversible future trend. Wiring harnesses, as the neural network of the electrical system, are of paramount importance. tesa wiring harness tapes, with their superior performance and diverse application scenarios, play an indispensable role in this process. As electric vehicles continue to gain popularity, tesa will continue to innovate and provide more high-performance wiring harness tape solutions to support the sustainable development of the automotive industry.

German tesa tape is widely used in a variety of industries, including industrial manufacturing, construction, automotive, and electronics. Specifically for data center (IDC) computer room cabinets, tesa tape products can be used in the following areas:

- Cable Management: Wire and cable management is crucial in data centers. tesa offers a variety of tapes for bundling and securing cables, ensuring they are neatly organized and reducing clutter and risk. For example, tesa's cable ties and electrical tapes can be used for this purpose, and tesa also offers fire-rated products.

- Identification and labeling: Cables and equipment in the equipment room need to be clearly labeled to facilitate maintenance and troubleshooting. tesa's marking tapes can be used to label cables and cabinets, helping technicians quickly identify and manage equipment.

- Thermal and electrical insulation: tesa's thermal and electrical insulation tapes can be used to protect cables and equipment in computer rooms, preventing overheating and electrical failures. For example, tesa's high-performance insulation tapes can be used in environments requiring high insulation performance.

- Fixing and mounting: tesa's double-sided adhesive tapes and mounting tapes can be used to mount and secure equipment inside cabinets and computer rooms, providing reliable adhesion and ensuring stable operation.

- Dustproofing and Sealing: Data center cabinets require effective dustproofing and sealing measures to prevent dust from entering and affecting equipment operation. tesa's sealing tapes can be used to seal cabinet doors and joints, providing effective dust protection.

Although tesa's products are very suitable for the above applications, the specific product selection needs to be determined according to the specific needs and environment of the computer room.

If you have any needs related to tesa tape wire harness in Taiwan, please contact our designated strategic partner, Qianbin Industrial.