In this article, we delve into the impact of PFAS and related regulations on the apparel industry.

PFAS is a type of DWR (durable water repellent) coating. DWR is used to produce water- and oil-repellent clothing, commonly found in outdoor and sportswear, but also in some workwear and medical applications. PFAS (perfluoroalkyl chemicals) are a class of synthetic chemicals that have been used in DWR coatings for many years. Despite their beneficial properties, PFAS are now restricted in the European Union due to their toxicity.

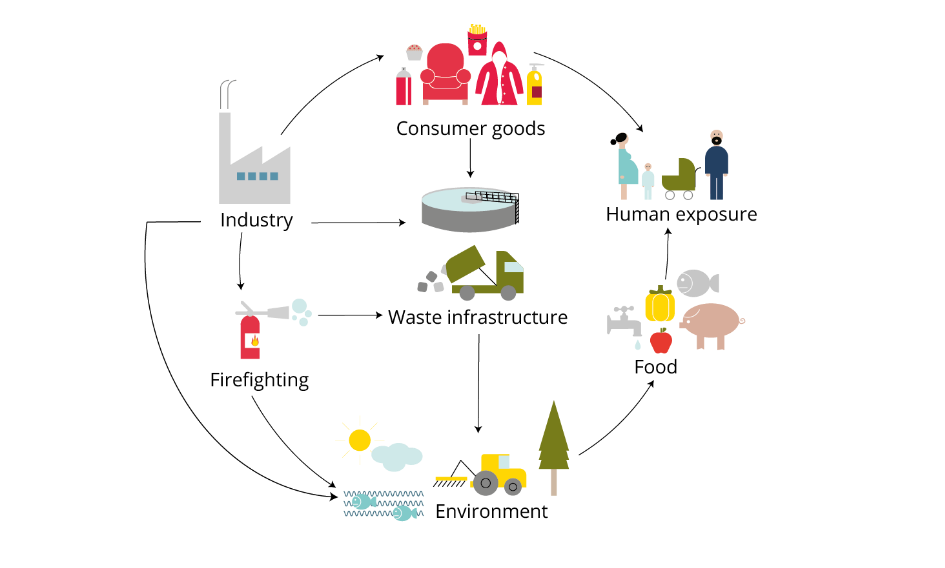

In 2009, the European Union began restricting the use of some PFAS derivatives. The EU is continually updating its directives and intends to ban these so-called "persistent chemicals" (another name for PFAS). This is because these chemicals are not naturally degradable. Once released into the environment, PFAS persist and can contaminate groundwater, surface water, and soil. The bioaccumulation of certain PFAS can also lead to serious health problems.

A new EU directive requires clothing and fabric manufacturers to change their DWR coating materials. Because C8-based PFAS (named for their chemical chain length) had long been banned, the industry shifted to using C6-based PFAS (short-chain PFAS). However, the latest EU restriction directive now includes C6-based PFAS. Let's examine the impact of this restriction.

Companies that previously used C6-based PFAS will need to use new materials to make fabrics waterproof and oil-resistant. Changes in coatings may also introduce new challenges, such as the risk of mold and mildew during transportation.

In early 2020, an affected manufacturer contacted Asotech. Their clothing products had developed mold during shipment from Asia to Europe. What had changed? They had changed the coating material used on their clothing to comply with new EU directives.

“The first shipment after we changed the coating on the clothing arrived in Europe in a terrible state. The clothes were completely moldy. We had never experienced this kind of damage before and we needed to understand the cause of the problem and avoid it in future shipments.”

Supply Chain Manager

Figure 1: Typical exposure pathways of PFAS (Source: European Environment Agency)

This customer used silicone desiccant packs in their plastic bags. However, when the clothing arrived at their destination, it was still in poor condition, resulting in unexpected costs and delays. We were eager to help them and asked the following questions:

- Does silicone desiccant have any effect on mold growth?

- Do I need to use more silicone desiccant in the plastic bag?

- Can AbsorGel Pouch prevent these moisture damages?

False protection

This leading European workwear manufacturer had been using silicone desiccant bags to protect its garments from moisture. They also packaged the garments in plastic bags, which were then placed in cartons for shipping and storage. The silicone desiccant's moisture barrier appeared to be sufficient to protect the garments from moisture damage.

But the fact is: silicone desiccant does not play a dominant role in moisture protection.

Figure 2: Silicone desiccant pack - Conclusion: Very limited effect

Their clothing uses a DWR coating containing PFAS, which was previously the primary reason their products remained mold-free during shipping. However, to comply with new EU directives, the clothing material has changed. Consequently, silicone desiccant packets are no longer effective in preventing mold growth on clothing made from the new material. Therefore, the original silicone desiccant provided only a false sense of moisture protection for these garments.

Introducing Peace of Moisture Mind®

The reality of the situation necessitated a quick solution to prevent damage to the goods during subsequent transportation. Our experts in Asia visited the production facility to inspect the product's condition prior to shipment and identify potential moisture-proofing solutions to improve the overall condition. Following the inspection, we developed a list of corrective actions, recommended dosages for our desiccant product, and conducted field testing. This process ensured the performance of our desiccant product (AbsorGel® Pouch D).

Our AbsorGel® Pouch D is a blend of 94% calcium chloride and starch. This product is used to absorb excess moisture inside crates, cartons, and other forms of packaging.

The water absorption of AbsorGel® pouches reveals that clothing products' previous moisture protection was insufficient. The water absorption of AbsorGel® pouches far exceeded the upper limit of silicone desiccant absorption. This suggests that DWR coatings containing PFAS were the key to protecting clothing products from moisture in the past.

The AbsorTest™ test showed that AbsorGel® pouches maintained relative humidity within plastic bags at a safe level. The products arrived mold-free. Our desiccant products also have a significant moisture absorption margin, providing protection against unexpected conditions such as extended storage or fluctuating shipping conditions.

Therefore, after Qianbin Industrial introduced the Jiefang brand and promoted it in Taiwan, feedback has been very positive so far from industry partners, ranging from B2B manufacturing clients to B2C e-commerce group-buying boutique storage. The principles of certification, R&D, and "you get what you pay for" are universally true. Qianbin strives to provide excellent service and build a collaborative ecosystem, hoping to share our high-quality products with customers across various industries.

Figure 3: AbsorGel® Pouch D ensures that the humidity during transportation is at a level that is not harmful to your garment products.

The ban on PFAS may have an impact on many industries. With the EU's further ban on all non-essential PFAS applications, many companies will face new challenges. Manufacturers in non-fabric and clothing industries may also encounter similar problems when adapting to the new directive.

“The logic of AbsorAudit and AbsorTest is suitable for all industries, products and packaging formats and can be used by all companies. It is based on our observation, measurement and monitoring, and is backed by our 25 years of professional experience.”

—Fredrik Lindberg, Regional Director for Northern Europe

Taiwan's textile and apparel industry's requirements for PFAS standards

Taiwan's textile and garment industry plays an important role in the global supply chain. As the EU's PFAS (perfluoroalkyl substances) standards become increasingly stringent, Taiwanese companies must also follow the corresponding standards to ensure that their products meet international market regulations.

1. Comply with international standards

Taiwan's textile and apparel companies need to understand and comply with the ban and restriction standards for PFAS in major markets such as the EU and the US. These standards generally include:

- Ban or restrict specific PFAS chemicals

- Testing and reporting PFAS levels

- Ensure supply chain transparency and compliance

2. Product testing and certification

To ensure that their products meet PFAS standards, companies should regularly test their products and obtain relevant certifications. These tests include:

- PFAS content detection

- Durable water repellent (DWR) effect test

- Other relevant environmental and safety certifications

3. Alternative materials and technologies

Due to the toxicity and environmental persistence of PFAS, companies need to find and use non-toxic or low-toxic alternative materials and technologies. These alternatives include:

- Use C6-based PFAS instead of C8-based PFAS

- PFAS-free DWR coating material

- Research, develop and apply innovative environmentally friendly materials

4. Supply Chain Management

It is important to ensure that every step of the supply chain complies with PFAS standards. Companies should:

- Work closely with suppliers to ensure their materials and products meet requirements

- Regularly review supplier compliance

- Train employees and suppliers to enhance their awareness and implementation of PFAS standards

5. Environmental and health considerations

When applying and managing PFAS, companies should consider their impacts on the environment and health and take appropriate measures:

- Reduce or eliminate the use of PFAS

- Improving standards of waste management and disposal

- Strengthening safety protection for employees and consumers

Conclusion

Faced with increasingly stringent standards for PFAS in the international market, Taiwan's textile and apparel industry must actively respond to ensure that its products meet regulations and maintain its competitiveness in the global market through innovation and responsible management practices.

AbsorGel® has been proven to be an effective solution for protecting garments and fabrics from moisture during transportation, and is also suitable for businesses looking to protect their brand and the environment. Taiwanese industrial users are encouraged to contact Chien-Bin Industrial for inquiries. #PFASFreePacking